Where Creativity Meets the Rigors of Pragmatism

By Gina Dostler

Commitment to community. California mojo. Beautiful glass tiles made with recycled glass. All underpin Oceanside Glasstile, founded by four Orange County friends. President and owner Sean Gildea takes pride in cultivating a company culture that allows birthday parades, factory adventure Wtours and creative camaraderie that makes exquisite tile.

Q: The company started out as four guys with OC roots who loved to surf.

A: Definitely. The original idea took seed with Boyce Lundstrom who had partnered with Bullseye Glass Company in the early ‘70s and ‘80s. He had pulled in his buddy Jon Stokesbary, an independent artist from South Laguna, along with a student of Jon’s, Don Pettey, to start a company that utilized scrap glass to make tile. This was a pretty novel idea back in the early ‘90s where nobody in the U.S. was making glass tile at that time. We were instrumental in pioneering the movement and continue on as a significant contributor of tile worldwide.

Q: And you were the fourth guy?

A: Lundstrom is my uncle and I was helping him out on my days off. I was a graduate of UC Santa Barbara and was nine months into my job at Deloitte LLP performing audits for large companies. I soon decided the world of accounting and that type of work environment just wasn’t right for me. So I said good-bye to wing-tips and slid into flip-flops to help start up Oceanside Glasstile full-time.

Q: Was location a key point to setting up shop?

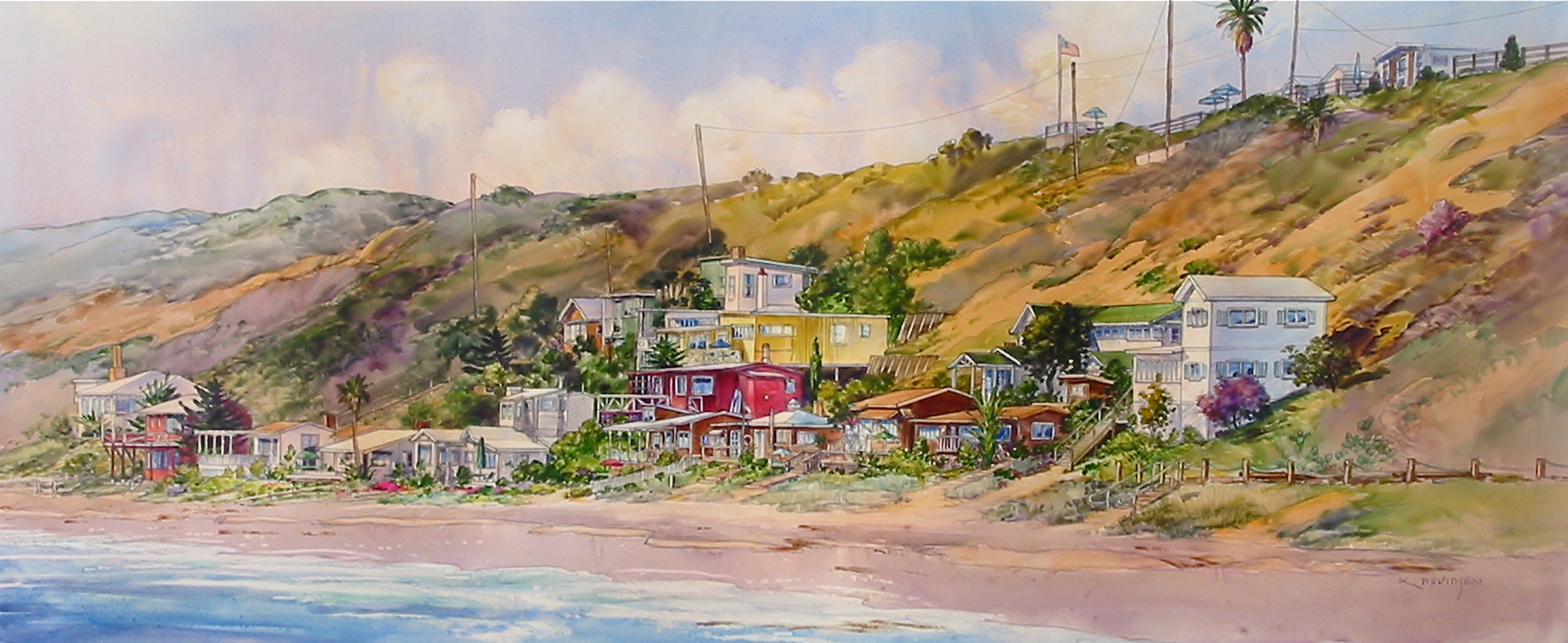

A: We’ve been a glass tile manufacturer from day one. And glass requires high heat so we were seeking an area that was not too hot. Besides the fact surfing was a big concern where quick ocean access was a necessity, Oceanside provided relatively inexpensive real estate and had a cooler environment. We started out with a 2,000 square foot building. It was super humble beginnings since now our warehouse is 94,000 square feet. Back then, Pettey lived in a fifth wheel trailer situated on the property. Despite the small quarters, as long as we could surf, it was all good.

Q: Your product is beautiful and green.

A: Yep, three LEED potential points. Our line of care and maintenance products, Ocean Care, is all environmentally friendly. And of course our tile is almost all recycled glass. Some colors are 85% recycled bottle glass. When it comes to the environment, the main concern is post consumer waste. For instance, someone’s polished off a Corona or a Coke and throws it away. It is picked up by the waste company or taken into a recycle center, crushed, cleaned and we receive it in a cullet or broken state. So we are pulling glass out of the waste stream. Trash into cash, as the saying goes.

Q: Where does the inspiration for your glass tile begin?

A: Nature inspires us. At the beach we notice colors, the shape of the sand, and the curves of the waves. The world inspires us. Our travels across Europe brings us interesting carvings and patterns in old churches and architecture. And we think, wow, that would be kinda cool in tile. Hundreds of geometric shapes surround us and inspire us. Also simply being a good listener and watching the market’s direction then putting our own spin into it gave us creative incentives for our tiles. Product development side of the business makes sure it works.

Q: Who heads up that department?

A: About four years into the story of Oceanside Glasstile, Johnny Marckx came on the scene. Another UC Santa Barbara graduate with some tile installation experience, he brought with him some new patterns and interesting shapes inspired by his experiences. Naturally the position fit right with his mojo, and we are able to carry on with beautiful, creative tiles that are commercially viable with manufacturability. I’d say we are a good blend of artistic creation that meets the rigors of engineering pragmatism.

Q: What is good to know about glass tiles?

A: Quality can vary. The process consists of forming by melting the glass at 2500 degrees, then taking it down to room temperature gradually where the temperature must stay consistent with the process so any latent stress in glass is avoided. This is part of the curing process. When a lower quality glass is made, the stress points in the glass due to poor curing can be initiated with any type of tension placed on it. Our tiles are very successful in pools due to the high quality that stands up to the water’s pressure. What we focus on is doing the best job to provide the highest quality and be sustainable at the same time.

Q: Your website speaks of your company’s “California Mojo.” What is that?

A: Really, when you come right down to it, it just means life is too short to get all wound up in everything. We encourage our employees to be interactive, work hard, but have fun in the process. Lunch times are for surfing, basketball, getting out and getting some air and exercise. It’s good for the mind and the body. Our company culture or “mojo” is relaxed, productive and fun all at the same time. We encourage camaraderie and that in turn brings everyone together in a positive manner and develops teamwork.

Q: Oceanside Glasstile is sold all over the world. Anywhere local we can get a glimpse of it?

A: The round Roman Pool at Pelican Hill. It’s the largest commercial pool in North America with over a million pieces of our tile in it. There are so many other places. I’ll have customers send me pictures with hey, we saw your tile in this restaurant. Many hotels, restaurants, casinos, medical facilities, cruise ships display our tile. It’s fun to know we are all over, but I don’t dwell on it. I get really excited about new products and colors, which is a testament to my passion for this industry. I’m super proud of our product located in many places, but stay focused on keeping the company moving forward in success.

Sean Gildea

Oceanside Glasstile

2293 Cosmos Ct.

Carlsbad, CA 92011

760-929-4000

www.glasstile.com

info@glasstile.com